TRANSPORT ANCHOR SYSTEMS

Inspired in the principles of operative flexibility, production simplification, total quality, precision and speed in the assemble, the transport anchor systems were developed to expedite the processes of transport and assemble pre-cast concrete elements.

Advantages of the systems:

-

Agility and speed in the deform, transport, load, unload and assemble;

-

Savings on expenditures with labor and rental of equipment such as cranes;

-

It allows perfect superficial finishing of the elements during the process;

-

Replaces the salient straps, easing the stacking;

-

Eliminates the undesirable and costly re-works for elimination of the straps and repair of the elements.

In order to calculate the effort in the anchor, it is necessary to consider several factors as well as the architecture of the cables, chains or belts:

-

Element’s own weight, including humidity;

-

Eventual asymmetric repartition of weight in elements with asymmetric shapes;

-

Statically uncertain lifting;

-

Lifting through multiple cables;

-

Suction effect between the element and the formworks;

-

Resistance of the concrete during transportation;

-

Vibration effects of the cranes or others equipments;

-

Safety and wind secondary values;

-

Tilted lifting traction in horizontally produced panels.

The “S” in the anchor is determined by the equation S = G . Y . a where:

b . e . c

G = Own weight with humidity

a = Suction factor to be taken in consideration in elements where the surface of contact with the shape, during the deform, is equal or greater than half of the total element surface;

-

Flat elements (flat slabs and panels) a = 1,3

-

Ribbed elements a = 1,6

-

If the contact surface is equal to 1, adopt a = 2,5

c = Number of anchors

e = Weight asymmetric distribution factor – For symmetry e=1

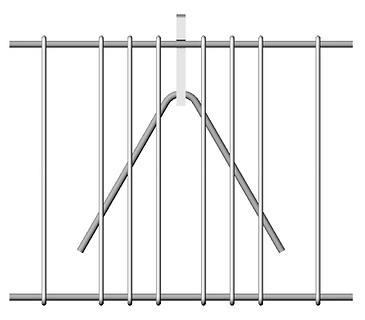

b = Loss factor due to the architecture inclination of the cables

Dimensioning of Load

-

Angle ß = 0º b = 1,00

-

Angle ß = 15º b = 0,96

-

Angle ß = 30º b = 0,86

-

Angle ß = 45º b = 0,70

-

Angle ß = 60º b = 0,50

10 TON

Non-recommended area

Y = Dynamic factor of the equipment of transportation and lifting

• Slow cranes Y = 1,3

• Hydraulic crane and derricks Y = 1,5

• Non-advised transportation with wheel loader or similar Y = 2

• Cranes with speed higher than 90m/min Y = 2,2

Zones of nominal capacity reduction of the anchors:

100% admissible F

Admissible F

Admissible F

Not Applicable

Threaded Transport Anchor System

The Threaded Transport Anchor System was developed with the goal of serving the transport of elements that require a good finishing and pre-casts elements lifted by the lateral, where the suspension point allowed the deform and transport the parts.

-

Threaded Lifting Clutch - TI

Reusable tool to be conected to the anchor (TS, TSA or TSL) after the concreting to perform the tumble and transportation of the pre-casted elements.

-

Threaded Lifting Clutch Adapter

-

Positioner Srew - TP

Reusable accessory that ensure that the anchor (TS, TSA or TSL) keep lower than the concrete surface, in a way to allow it's protection against corrosion.

*workloads considered for concrete with resistance that is equal or greater than 15 MPa.

Accessory used with the Threaded Lifting Clutch when the surface of suspension point is not flat. It's usually used in panels with male-female edge. Tailored product.

Reusable element developed to protect the anchor thread.

-

Plastic Screw Finishing - TAP

-

Reinforcement Clamp

Element developed to substitute the additional reinforcement made with CA-50 rebar, making viable the lifting of lower thickness panels produced horizontally.

We list below three types of anchors that may be used in specific situations:

-

Threaded Anchor - TS

Anchor indicated to transport beams, pillars and ladders.

-

Reinforced Threaded Anchor - TSA

*Workloads considered for concrete with resistance equal or greater than 15 MPa.

Tailored TS: the dimension “H” can be increased under consultation.

Element with reinforcement, indicated for panels transportation. It could also be used for beams and pillars.

*Workloads considered for concrete with resistance equal or greater than 15 MPa.

Tailored TS: the total length can be increased under consultation.

-

Slab Threaded Anchor - TSL

Element indicated for slab transportation. It can also be used for panels produced in the tilt-up system.

*Workloads considered for concrete with resistance equal or greater than 15 MPa.

THREADED ANCHOR - TS REINFORCEMENT

Reinforcement recommended for cables working 90°:

Reinforcement recommended for oblique angle cables:

REINFORCED THREADED ANCHOR - TSA ADDITIONAL REINFORCEMENT

Reinforcement recommended for oblique angle cables:

When these anchors are in the lateral of panels or other elements produced horizontally that must necessarily be lifted or rotated for the vertical position, we recommend the following additional reinforcement.

-

CA-50 rebar

-

Reinforcement clamp

SLAB THREADED ANCHOR - TSL REINFORCEMENT

All cases:

Fast Transport Anchor System

The Fast Transport Anchor System was developed with the goal of serving the transport of elements with agility and security. In addition to the simplicity of the hitch of the clutch in the anchor, it is possible to remove it from a distance, which makes the operation safer, since it doesn't requires the presence of a professional to realize this operation.

Below we list the components used in this system:

-

Fast Lifting Clutch - IRT

Reusable tool to be hicth to the anchor (LIFT) after the concreting in order to perform the transportation of the pre-casted elements.

-

Superior Positioner / Recess Former - PS

Disposable accessory (PS) used to ensure that the anchor remain correctly allocated in the concrete.

-

Inferior Positioner - BC

Plastic element that keeps the anchor perpendicular to the pre-cast element used in slabs and tilt-up panels.

-

Cover Plate - TRL

Plastic element used to cover the recess left by the Superior Positioner / Recess Former .

We list below two types of anchors that may be used in specific situations::

-

Anchor - LIFT

Anchor preferably recommended to the transportation of beams, pillars and panels produced vertically.

*Workloads considered for concrete with resistance equal or greater than 15 MPa.

Tailored LIFT Anchor: the dimension “H” can be increased under consultation.

-

Lift with Craved Bar

Anchor developed for transportation of slabs and panels produced through Tilt-up System. It also can be used for the transportation of other elements.

LIFT ANCHOR REINFORCEMENT

We list below illustrations of anchor's reinforcement and confinement:

LIFT ANCHOR WITH CRAVED BAR REINFORCEMENT

Spherical Transport Anchor System

The Spherical Transport Anchor System was developed with the goal of serving the transport of elements with agility and security. It's characteristic is the possibility of rotating pre-cast concrete elements.

We list below the elements of this system:

-

Spherical Lifting Clutch - IES

Reusable tool to be hicth to the anchor (TES) after the concreting in order to perform the transportation of the pre-casted elements.

*Workloads considered for concrete with resistance equal or greater than 15 MPa.

-

Spherical Positioner / Recess Former - TPE

Reusable accessory (TPE) used to ensure that the anchor remain correctly allocated in the concrete.

-

Spherical Anchor - TES

Anchor preferably recommended to the transportation of beams, pillars and panels produced either vertically or horizontally.

*Workloads considered for concrete with resistance equal or greater than 15 MPa.

SPHERICAL ANCHOR - TES REINFORCEMENT

Reinforcement recommended for oblique angle cables:

STIRRUP CONCENTRATION

PILLAR

To tumble pre-cast elements, consider 50% of anchor capacity:

ADMISSIBLE F

FREIGHTAGE

Anchors Used in Pairs

When the efforts applied in the suspention points of the pre-cast elements are superior to the workload of the anchor, the soluction could be locate the anchors in pairs.

We recommend the usage of Compensation Device for Double Points (for more information, acess Transportation Accessories).

The distance between the anchors must be twice the anchor length of the anchor with a minimum of 40 cm.